I find the polyolefin compounds market to be a dynamic and rapidly evolving sector, driven by the increasing demand for lightweight, durable, and cost-effective materials across various industries. As of 2024, the global polyolefin compounds market is valued at approximately USD 25.8 billion, with projections indicating it will reach USD 35.6 billion by 2030, growing at a compound annual growth rate (CAGR) of around 5.5%. This growth is fueled by the rising adoption of polyolefins in packaging, automotive, and construction applications, where their versatility and recyclability make them a preferred choice. The market’s expansion is also supported by increasing industrialization in emerging economies and the growing emphasis on sustainable materials. My analysis suggests that the demand for polyolefin compounds is closely tied to global trends in manufacturing and environmental regulations, which are pushing industries to adopt materials that balance performance with eco-friendliness. The Asia-Pacific region, in particular, plays a significant role in driving this market due to its robust manufacturing base and growing consumer demand.

When I look at the top segments in the polyolefin compounds market, I see polyethylene (PE) and polypropylene (PP) as the dominant types, with polypropylene holding the highest share. In 2024, polypropylene accounts for nearly 55% of the market due to its widespread use in automotive parts, packaging films, and consumer goods. Its popularity stems from its excellent chemical resistance, flexibility, and low cost, making it ideal for applications requiring durability and lightweight properties. Polyethylene, while significant, follows closely, particularly in packaging and agricultural films. Other segments, such as ethylene-vinyl acetate (EVA) and polyolefin elastomers, are gaining traction in niche applications like footwear and adhesives, but they hold a smaller share. My observation is that polypropylene’s dominance is likely to continue, driven by innovations in compounding techniques that enhance its performance for specialized applications, such as high-impact automotive components.

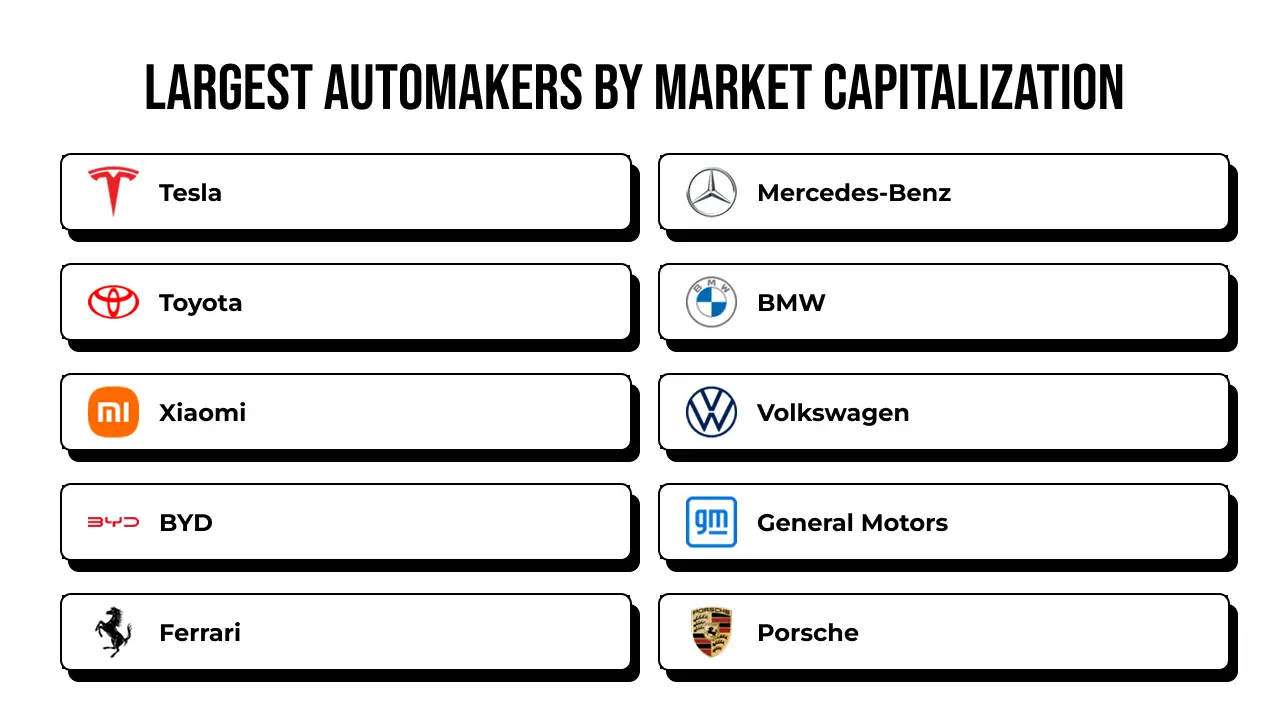

The competitive landscape of the polyolefin compounds market is vibrant, with several key players driving innovation and market growth. Major companies include LyondellBasell Industries, ExxonMobil Corporation, and SABIC. LyondellBasell stands out as a top player, leveraging its extensive portfolio of advanced polyolefin compounds tailored for automotive and packaging industries. ExxonMobil also holds a significant share, focusing on high-performance polyethylene and polypropylene solutions. Other notable companies include BASF SE and Dow Inc., which are investing heavily in research to develop sustainable and high-strength compounds. I’ve noticed that these companies are increasingly focusing on strategic partnerships and acquisitions to expand their market presence, particularly in emerging regions. Their ability to innovate and meet stringent regulatory requirements gives them a competitive edge in this crowded market.

Geographically, I see the Asia-Pacific region leading the polyolefin compounds market, with China and India as the top countries. China dominates due to its massive manufacturing sector, particularly in automotive and packaging, contributing over 40% of the global market share in 2024. India follows, driven by rapid industrialization and infrastructure development. North America, particularly the United States, holds a significant position due to its advanced automotive and construction industries. Europe, led by Germany, is also a key player, with a focus on sustainable and high-performance compounds. My analysis indicates that these regions will continue to drive demand, with Asia-Pacific’s growth outpacing others due to its expanding industrial base and favorable government policies.

The latest innovations in the polyolefin compounds market are truly exciting, with a strong focus on sustainability and performance. One notable advancement is the development of bio-based polyolefins, which reduce reliance on fossil-based raw materials. Companies are also introducing recyclable polyolefin compounds that maintain high performance while meeting circular economy goals. Another trend is the use of advanced compounding techniques, such as nanotechnology, to enhance mechanical properties like strength and flame resistance. I’ve observed that the automotive industry is increasingly adopting lightweight polyolefin compounds to improve fuel efficiency, while the packaging sector is leaning toward flexible, recyclable films. These trends reflect the market’s shift toward eco-friendly solutions and high-performance materials, aligning with global sustainability goals and regulatory pressures.